ZWT has a department specialized in milling, supported by a CAM department, carries out mechanical processes of construction and modification of the moulds. Thanks to its specialized team with a wide knowledge of the market, ZWT is able to realize high-quality designs to satisfy every specific customer’s request.

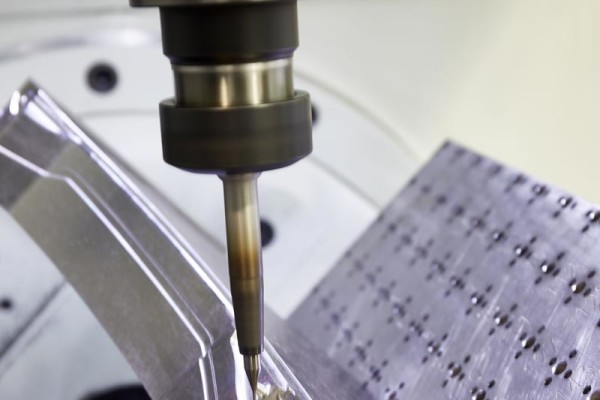

The milling department is equipped with the most advanced technologies to carry out every single type of process on the mould: there are modern machineries for mould construction of different dimensions beyond the necessary tools to modify moulds. Our machinery park includes milling machines and numerical controlled machines connected to the CAM department.

Our milling machinery park is always in development: ZWT’s goal is to internalize an EDM machine and 5-axis milling center for superfinishing of medium and large dimension. With this approach, the company will be able to work with precision and to offer high-quality processes in respect of the delivery times.

It also deals with mould construction, modification and finishing, ZWT offers an EXPRESS service for maintenance and assistance, in order to guarantee high quality and perfect functioning of every mould.