WHITE ROOM

In 2015, we have updated our specialized welding center, microincisione® and laser engraving that exists from 13 years in Brescia area.

We offer innovative ideas to repair the damaged or used moulds or to modify them. The welding patents and the prestigious recognition of AUBERT&DUVAL, FA.RO ACCIAI, LUCCHINI SIDERMECCANICA and STANDEX guarantee the high quality of our performances.

- The laser welding is a very successful method of welding for the industry and for the high precision toolmakers, because it is an extremely precise repair technique that causes a minimal thermal input.

Our laser welding stations are equipped with a solid-state pulse laser in the range of 150 and 200 watt. - The TIG welding with the preheating furnace allows a perfect execution of welding beads on steel cores and cavities and other materials.

- The Plasma welding is a welding technique, especially for the moulding steels, characterized by a restrained heat contribution and a good precision.

- The MMA welding is an arc welding technique suitable for welding beads of elevated thickness and characterized by an easy portability.

- The MIG and MAG welding is a wire welding technique suitable for massive thick welding beads and the repair of big parts.

- The brazing is a welding technique that allows to realize joints of many dimensions leading to fusion only the brazing alloy, keeping intact the items.

- Repair of damaged photoengraved moulds in collaboration with STANDEX

- Urgent welding operations without notice with delivery in 4 hours.

- Decimal welding beads to repair corners

- Removal and closure of injection points and tunnels, even underwater.

- Ribs closure until 80mm depth

- Welding beads up to 20mm on Z axis and over

- Welding beads on basis material such as 1.2311/12, 1.2343/44, 1.2083, 1.2316, 1.2379, 1.1730, 1.2714

- Welding beads on special materials such as MoldMAX, beryllium copper, AMCO, MARVAL, aluminium.

For all our welding techniques, we provide the WHITE ROOM EXPRESS service, that offers reparations of the moulds at the customer’s company, following the national and international regulations. Our electrodes are produced internally, following the moststrict quality standards. Wires are available from 0,2mm diameter up to 0,8mm.

| WIRE TYPES | DIAMETER ø | CHARACTERISTICS | STEEL TYPE |

|---|---|---|---|

| SALTEX 300 | 0.2 | Electrode for laser welding electrode suitable for a generic use. Excellent colour and easy to polish | 1.2311 1.2312 1.2738 |

| SALTEX 300 | 0.3 | ||

| SALTEX 300 | 0.4 | ||

| SALTEX 300 | 0.5 | ||

| SALTEX 300 | 0.6 | ||

| SALTEX 300 PHOTO | 0.4 | Electrode for laser welding electrode designed to guarantee an optimal mould photoengraving | |

| SALTEX 300 MIRROR | 0.4 | Electrode for laser welding electrode designed to guarantee an optimal mould polishing. | |

| SALTEX 400 | 0.5 | Electrode for laser welding electrode suitable to repair high hardness destined to injection mould. Excellent colour and very easy to polish. Appropriate for 40-44 HRC | 1.2343 1.2344 1.2714 |

| SALTEX 400 | 0.6 | ||

| SALTEX 460 | 0.5 | Electrode for laser welding electrode suitable to repair high hardness steel destined to injection moulds. Excellent colour and very easy to polish. Appropriate for 46-50 HRC | |

| SALTEX 460 | 0.6 | ||

| SALTEX Hot work | 0.5 | Electrode for laser welding electrode suitable to repair steels used for die-casting or hot forming moulds | 1.2343 1.2344 1.2714 |

| SALTEX Hot work | 0.6 | ||

| SALTEX Sharp Edge | 0.5 | Electrode for laser welding electrode suitable to repair steels destined to the production of blades and sheers. Particularly appropriate to repair ruined corners | 1.69375 |

| SALTEX Cr 13 INOX | 0.5 | Electrode for laser welding electrode suitable to repair inoxidable martensitic steels with a 13% of Cr. Excellent colour and very easy to polish. | 1.2083 AISI 420 |

| SALTEX Cr 13 INOX | 0.6 | ||

| SALTEX Cr 16 INOX | 0.5 | Electrode for laser welding electrode suitable to repair inoxidable austenitic steels. Excellent colour and very easy to polish. | 1.2316 AISI 430 |

| SALTEX Cr 16 INOX | 0.6 | ||

| SALTEX 18/10 INOX | 0.2 | Electrode for laser welding electrode for beryllium copper alloys. Excellent colour and very easy to polish | AISI 304 AISI 304L AISI 316 AISI 316L |

| SALTEX 18/10 INOX | 0.4 | ||

| SALTEX 18/10 INOX | 0.6 | ||

| SALTEX 18/10 INOX | 0.8 | ||

| SALTEX MoldMAX® | 0.4 | Berillium copper alloys MOLDMAX® | Leghe rame-berillio MOLDMAX® |

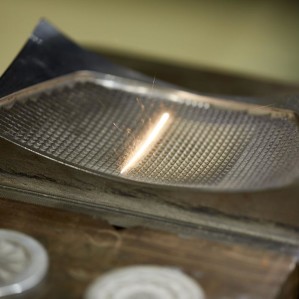

The MICROINCISIONE® is our innovative and exclusive mechanical process, invented and developed by Zanola ZWT, that achieves finishing similar to the EDM and photoengraving.

- Applicability: It is possible to engrave every material up to 50HRC, regardless of the chemical analysys, including the inoxidable steels, aluminium or special alloys.

- Versatility: The surface can have corners as in the electroerosion and rounded as the photoengraving.

The mould surface can be shiny or opaque according to the customer needs. The deformation grades are similar to the photoengraving.

- Immediate reactivation: In case of extensive use, wrong maintenance or breakages during the moulding phase, the mould can be repaired without any precautionary polishing.

- Endurance: The finishing is resistant to high temperatures and to usury resulting from the moulding phase thanks to the hardening and the consequent increase that concerns the mechanical properties of the engraved steel surface outer layer.

- Custom-Tailored: It is possible on every surface delimiting, upon request, areas with different types of finishing and offers the possibility to realize graphics and logos.

- Velocity: The production time is short and consequently the deliveries are fast.

Richiedi informazioni sul servizio:

| FINISHING CODE | DRAFT ANGLE | PRE-POLISHING SUGGESTED FOLLOWING THE “ SCALA ZANOLA” | FINISHING TYPE | NOTES |

|---|---|---|---|---|

| TEXTURING (Developed following the customer’s drawing) | 1,5° | SZ07 | -- | For every material |

| ZC1605 | 3° | SZ03 | Standard | |

| ZC2405 | 2,5° | SZ03 | Standard | |

| ZC4605 | SZ05 | Standard | Suggested on large surfaces | |

| ZC6005 | 2° | SZ07 | Standard | For every material |

| ZC1505 | 1° | SZ07 | Standard | |

| ZC2205 | SZ07 | Standard | ||

| ZC9015 | SZ09 | Standard | ||

| ZC705 | 2,5° | SZ07 | Anti Scratch | For every material |

| ZC1105 | SZ07 | Anti Scratch | ||

| ZC1705 | SZ05 | Anti Scratch | ||

| ZC2305 | SZ03 | Anti Scratch | ||

| ZC2805 | SZ03 | Anti Scratch | ||

| ZC3305 | SZ03 | Anti Scratch | ||

| ZC3905 | SZ03 | Anti Scratch | ||

| ZC4600 | SZ05 | Anti Scratch | ||

| ZC46P5 | SZ03 | Anti Scratch | For every material |

The engraving and laser marking are innovative systems of laser processing that lead to achieve high quality text and images.

- Realizable on moulds and mechanical particulars in general

- Realizable on engraved cores

- Engraving depth up to 0,8mm

- Wide engraving range: logos texts drawings in 2D and 3D

- Marking and items numeration

- Graphic files elaboration in the most famous formats

- Name and Surname engraving

- Barcode engraving

- + Welding

We offer innovative ideas to repair the damaged or used moulds or to modify them. The welding patents and the prestigious recognition of AUBERT&DUVAL, FA.RO ACCIAI, LUCCHINI SIDERMECCANICA and STANDEX guarantee the high quality of our performances.

The WHITE ROOM Welding Centre includes:- The laser welding is a very successful method of welding for the industry and for the high precision toolmakers, because it is an extremely precise repair technique that causes a minimal thermal input.

Our laser welding stations are equipped with a solid-state pulse laser in the range of 150 and 200 watt. - The TIG welding with the preheating furnace allows a perfect execution of welding beads on steel cores and cavities and other materials.

- The Plasma welding is a welding technique, especially for the moulding steels, characterized by a restrained heat contribution and a good precision.

- The MMA welding is an arc welding technique suitable for welding beads of elevated thickness and characterized by an easy portability.

- The MIG and MAG welding is a wire welding technique suitable for massive thick welding beads and the repair of big parts.

- The brazing is a welding technique that allows to realize joints of many dimensions leading to fusion only the brazing alloy, keeping intact the items.

Services provided:- Repair of damaged photoengraved moulds in collaboration with STANDEX

- Urgent welding operations without notice with delivery in 4 hours.

- Decimal welding beads to repair corners

- Removal and closure of injection points and tunnels, even underwater.

- Ribs closure until 80mm depth

- Welding beads up to 20mm on Z axis and over

- Welding beads on basis material such as 1.2311/12, 1.2343/44, 1.2083, 1.2316, 1.2379, 1.1730, 1.2714

- Welding beads on special materials such as MoldMAX, beryllium copper, AMCO, MARVAL, aluminium.

For all our welding techniques, we provide the WHITE ROOM EXPRESS service, that offers reparations of the moulds at the customer’s company, following the national and international regulations. Our electrodes are produced internally, following the moststrict quality standards. Wires are available from 0,2mm diameter up to 0,8mm.

WIRE TYPES DIAMETER ø CHARACTERISTICS STEEL TYPE SALTEX 300 0.2 Electrode for laser welding electrode suitable for a generic use.

Excellent colour and easy to polish1.2311

1.2312

1.2738SALTEX 300 0.3 SALTEX 300 0.4 SALTEX 300 0.5 SALTEX 300 0.6 SALTEX 300 PHOTO 0.4 Electrode for laser welding electrode designed to guarantee an optimal mould photoengraving SALTEX 300 MIRROR 0.4 Electrode for laser welding electrode designed to guarantee an optimal mould polishing. SALTEX 400 0.5 Electrode for laser welding electrode suitable to repair high hardness destined to injection mould. Excellent colour and very easy to polish.

Appropriate for 40-44 HRC1.2343

1.2344

1.2714SALTEX 400 0.6 SALTEX 460 0.5 Electrode for laser welding electrode suitable to repair high hardness steel destined to injection moulds. Excellent colour and very easy to polish.

Appropriate for 46-50 HRCSALTEX 460 0.6 SALTEX Hot work 0.5 Electrode for laser welding electrode suitable to repair steels used for die-casting or hot forming moulds 1.2343

1.2344

1.2714SALTEX Hot work 0.6 SALTEX Sharp Edge 0.5 Electrode for laser welding electrode suitable to repair steels destined to the production of blades and sheers. Particularly appropriate to repair ruined corners 1.69375 SALTEX Cr 13 INOX 0.5 Electrode for laser welding electrode suitable to repair inoxidable martensitic steels with a 13% of Cr. Excellent colour and very easy to polish. 1.2083

AISI 420SALTEX Cr 13 INOX 0.6 SALTEX Cr 16 INOX 0.5 Electrode for laser welding electrode suitable to repair inoxidable austenitic steels. Excellent colour and very easy to polish. 1.2316

AISI 430SALTEX Cr 16 INOX 0.6 SALTEX 18/10 INOX 0.2 Electrode for laser welding electrode for beryllium copper alloys. Excellent colour and very easy to polish AISI 304

AISI 304L

AISI 316

AISI 316LSALTEX 18/10 INOX 0.4 SALTEX 18/10 INOX 0.6 SALTEX 18/10 INOX 0.8 SALTEX MoldMAX® 0.4 Berillium copper alloys MOLDMAX® Leghe rame-berillio MOLDMAX® - The laser welding is a very successful method of welding for the industry and for the high precision toolmakers, because it is an extremely precise repair technique that causes a minimal thermal input.

- + Microincisione

The MICROINCISIONE® is our innovative and exclusive mechanical process, invented and developed by Zanola ZWT, that achieves finishing similar to the EDM and photoengraving.

MICROINCISIONE® features:- Applicability: It is possible to engrave every material up to 50HRC, regardless of the chemical analysys, including the inoxidable steels, aluminium or special alloys.

- Versatility: The surface can have corners as in the electroerosion and rounded as the photoengraving.

The mould surface can be shiny or opaque according to the customer needs. The deformation grades are similar to the photoengraving.

- Immediate reactivation: In case of extensive use, wrong maintenance or breakages during the moulding phase, the mould can be repaired without any precautionary polishing.

- Endurance: The finishing is resistant to high temperatures and to usury resulting from the moulding phase thanks to the hardening and the consequent increase that concerns the mechanical properties of the engraved steel surface outer layer.

- Custom-Tailored: It is possible on every surface delimiting, upon request, areas with different types of finishing and offers the possibility to realize graphics and logos.

- Velocity: The production time is short and consequently the deliveries are fast.

Richiedi informazioni sul servizio:

FINISHING CODE DRAFT ANGLE PRE-POLISHING SUGGESTED FOLLOWING THE “ SCALA ZANOLA” FINISHING TYPE NOTES TEXTURING (Developed following the customer’s drawing) 1,5° SZ07 -- For every material ZC1605 3° SZ03 Standard ZC2405 2,5° SZ03 Standard ZC4605 SZ05 Standard Suggested on large surfaces ZC6005 2° SZ07 Standard For every material ZC1505 1° SZ07 Standard ZC2205 SZ07 Standard ZC9015 SZ09 Standard ZC705 2,5° SZ07 Anti Scratch For every material ZC1105 SZ07 Anti Scratch ZC1705 SZ05 Anti Scratch ZC2305 SZ03 Anti Scratch ZC2805 SZ03 Anti Scratch ZC3305 SZ03 Anti Scratch ZC3905 SZ03 Anti Scratch ZC4600 SZ05 Anti Scratch ZC46P5 SZ03 Anti Scratch For every material - + Laser Engraving

The engraving and laser marking are innovative systems of laser processing that lead to achieve high quality text and images.

The laser engraving features are:- Realizable on moulds and mechanical particulars in general

- Realizable on engraved cores

- Engraving depth up to 0,8mm

- Wide engraving range: logos texts drawings in 2D and 3D

- Marking and items numeration

- Graphic files elaboration in the most famous formats

- Name and Surname engraving

- Barcode engraving